METRIT CHEMICALS P.LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to METRIT CHEMICALS P.LTD

Iron Phosphating

Salient Features:

- Removes thin films of oil

- Forms a light amorphous iron phosphate coating on ferrous and steel components.

- Forms zinc phosphate coating on galvanized steel surfaces by converting a part of the zinc surface into an integral zinc phosphate coating.

- Forms aluminium phosphate coating on aluminium surfaces. The phosphate coatings so formed will be a good base for subsequent liquid painting and powder coating.

- May be used as 3-stage, or 5-stage, depending upon type and degree of oils and superficial impurities.

- My be used by dip process, or by spray process

- In spray process, dwell time is 60 to 120 seconds.

- In dip process, duration of dip is 7 to 10 minutes.

- Build-up of iron phosphate coating: 50 to 60 mg./sq.ft.

- Build-up of zinc phosphate coating on galvanized steel surfaces will be around 50 -150 mg/sq.ft.

Build-up of aluminium phosphate coating: 50 to 100 mg./sq.ft.

Zinc Phosphating Phosphate Conversion Coating

Salient Features:VANGUARD RCFunctions at temperature range of: 65 to 70 deg. C. In about 3 to 5 minutes' of dip duration, forms velvet-smooth, dense, very hard and crystalline calcium modified zinc phosphate coating. The Coating wt: between 250 and 400 mg/s.ft. It is an Ideal base for subsequent painting liquid paint, powder coating,The Calcium present acts as the in-built grain refiner in the phosphating bath and hence eliminates the need for a separate activation or a titanium pre-rinse step. Thus, the introduction of calcium not only results in the formation of coatings of good quality, but also contributes to the economy of the process through the elimination of the pre-rinse process stage

Trication Coating

ZINPOFOR-TCI gives light, smooth, dense, crystalline zinc trication phosphate coating (zinc–nickel-manganese phosphate coating), firmly adherent to, and integral with the surface being treated. the build up of the coating is around: 100 to 400 mg/s.ft. the treated surface is ideal for liquid painting and powder coating.

Manganese Phosphating

We have two products VANGUARD M & DUROPHOS M

DUROPHOS-M,Produces smooth, crystalline, highly porous, manganese-iron phosphate coatings, Build-up of coating weight: 1500 to 4000 mg/ s.ft. In a dip duration of 10 to 30 minutes, depending upon the steel surface, and the type of surface preparation. absorbs and retains oils, and sealing waxes; Provides excellent corrosion resistance, and breaking-in properties on wearing parts.

VANGUARD-M,Produces, smooth, crystalline, highly porous, manganese-iron phosphate coatings Build-up of coating weight: 700 to 1200 mg/sft. Dip duration 5 to 15 minutes, depending upon the steel surface, and the type of surface preparation. absorbs and retains oils, and sealing waxes;Provides excellent corrosion resistance, and breaking-in properties on wearing parts. Only one chemical is used for both make-up and for replenishment. Formulation of chemical includes a self-regenerating type of accelerator.

Hot Zinc Phosphating

Salient Features:

DUROPHOS-25 functions as a 3.54% solution at optimum operating temperature of 85-90 Deg. C.

DUROPHOS-25 gives heavy, absorptive zinc phosphate coating wt between 1000 and 2500 mg/sq ft, in a dip duration of 10 to 30 minutes, which may be oiled, waxed or given a coat of liquid paint for outstanding corrosion resistance.

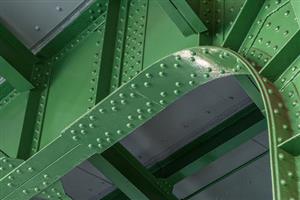

Effluent Treatment Plant

JETTALIZER ( Hot Black Oxidizing Chemical)

Black oxide coatings are chemical conversion coatings, applied as a protective or decorative finish. Black oxide coatings have properties that make them ideal for certain applications. They are suited for moving parts or sliding surfaces that cannot tolerate the dimensional build-up of the more corrosion-resistant finishes. JETTALIZER bath operates at between 136 and 143 Degrees C.

Room Temperature Scale Removerdescaling

Koldblak functions at 20o+ C. It blackens steel and cast iron components. Cold blackening process is simple and safe to operate and produce high quality results.

Koldblak forms a copper selenide coating, which when sealed with appropriate oil, wax, etc will provide corrosion resistance to the treated components. Comes in liquid and gel form.

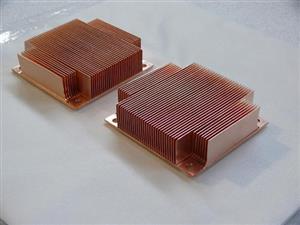

Phosphating Plants

ALUGOLD chromating chemical is designed to treat aluminium, and its alloys

ALUGOLD gives yellow chromate coating, giving low coating weight and higher conductivity; the corrosion resistance is very good, and provides a good adhesion base for paint film, whether it is powder coating or liquid painting.

ALUGOLD is used as a 3% solution;

Functioning at Room Temperature (25oC)

Dip duration: 3 to 5 minutes.

Surface Treatment Chemical

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.